![]()

THEME IX

DIESEL-ELECTRIC LOCOMOTIVE OVERHAUL AND REPAIR

(from 1972 to 1995 third part)

The big stages of these last years

Changes to the diesel-electric locomotives

The evolution of maintenance cycles

The evolution of workshop cycles and production facilities

The big stages of these last years

After the upheavals that QM knows, at the time of the passage of the vapor about the diesel, the story of the company would have been able to congeal. On the contrary. The course of this story seems to accelerate throughout the last twenty years of the 20th century which interest us here.

Technical advances in rapid succession, strengthening the concept of competitiveness, increasingly strong external pressures, will oblige the establishment to call itself in question, unceasingly, and at will be reformed in order to preserve its row. It is for better giving an account of this speeding-up of the story of QM, than some of the facts most outstanding covering period 1975-1995 were gathered, and thus make it possible to better determine realities of the life of an industrial company of this size at the dawn of the 21e century.

Changes to the diesel-electric locomotives

The Technical Service of Quatre-Mares sets and monitors the application of modifications. As such it assure the updating and management of drawings (circulation and distribution) and manages the innovations presented by staff and which aim to improve safety, maintenance and conduct in-service locomotives.

Among the striking facts which marked out the Seventies and Eighties, some were going to relate to often important modifications of the locomotives. Thus, after one break-in period to the diesel activity, the agents of Q.M., will quickly, proceed to transformations in the structure of the locomotives. Indeed, in spite of the care taken in the design engineering and the manufacturing of the diesel-electric locomotives, these last were going quickly to let appear some weaknesses.

The first of the modifications of great scale, on these locomotives, was without question that which consisted in reinforcing their driving cabins. These cabins, whose steel framework was only covered with a “polyester resin mask”.one protection, unfortunately illusory , in the event of collision. It will then be decided to reinforce the driving cabins by the installation with a steel shield.

In 1974, the series of CC 72001-020 (the second series is equipped home) was going to start a Quatre-Mares, one large-scale operation called: "reinforcement of cabins".

This type of intervention would be extended to all series of machines in the years that followed. On the A1A-A1A 68000 68500, this requires the complete reconstruction of cabs. On this series the special locomotive, the original cabs were interchangeable.

Cabin destroyed following a collision

They were designed to be placed one piece on the machine, and to be reviewed as a subset as well as the engine, unit cooling etc... They were fixed to the frame of the locomotive by five blocks. For this series it was thus necessary to rebuild directly on the frame the complete skeletons of cabins. It is among others, in this time when were put deposited the bays of angles of cabins.

A removable cabin of 68000

In 1977, and for the series A1A-A1A 68000 only, was going to begin jointly the interventions of Semi Lifetime. In fact the policy of maintenance which had been defined at the time of their putting into circulation, had envisaged, when those would have arrived approximately at half of their life (estimated at approximately 25 years), an operation of great scale in order to enable them to continue their service until their depreciation. All the 68000 passed to QM were renovated. The disappearance of the towed material with heating vapor will also involve starting from this date the demounting of boilers “VAPOR” of the A1A-A1A 68000. This operation required the installation of “blemish” instead of the boiler. The weight and the site of this ballasting were studied to compensate for caused imbalance.

On the right side the building site Mie-Life 68000

The reinforcement of the chassis of the CC 72000 is a necessity from 1978, as a result of the emergence of cracks on their framework generated by the deformation at the time of their inscription in the curves. The expertises and the modifications, in particular by the addition of reinforcements, will cure it.

Among the technical tests and improvements brought on the 67400, we will quote this one who which consisted in equipping two of them, the 67419 and 67537, of a rheostatic brake, of transverse shock absorbers and of adapted gear ratios allowing him to reach without problem 160 km/h.

In spite of this aptitude, recognized on June 7th, 1984 at the end of official tests, and which retained the hypothesis of an extension expressed where necessary by the "Transport", these machines will be "given to the origine type” in 1994.

Originally painted with paint "alkyd", the 67,401 to 67,538 will, from 1983, painted with painting "polyurethane", like their counterparts numbered from 67,539 to 632. This painting providing better performance in service.

In the early 90's, few locomotives of the series BB 67300/400, partially destroyed as a result of fire from various sources had to be rebuilt. This reconstruction has raised the issue of replenishment of some electrical equipment. Of old design, this equipment proved very expensive to rebuild. The economics has led to the decision to re-equip these machines with PLCs programmable. GEC Alsthom has already tested this solution in 1983 on the BB 67303 is a PLC ALSTHOM AME-10 was selected and the application of the BB 67303 adapted for locomotives BB 67326, 67348, 67459, 67528, 67559, 67579 , 67606, 67620.

The improvement of the security, bound to the conduct of locomotives, was constantly the object of implementation of new systems aboard machines. (the eve automatic, repetition of the signals in driver's cabs, blinking of warning lights in case of alert, memorization of the attentiveness). On some locomotives repaired Four Mares, these systems have been planned of construction. The others, are equipped at their passages in revision.

A series of serious accidents between 1985 and 1988, however, triggered the establishment, at a rapid pace, new automation for make up certain errors.

After the tragic accident of Flaujac, where two locomotives coming the other way around on a unique way, collided on August 3rd, 1985, it is decided to set up an equipment of radio link allowing real time communications between the drivers, between the regulator and the drivers and finally between these last ones and train stations. The system sends an alarm signal to locate any incident and identify the place from which it was issued. It also allows the sending of an alert, requiring cessation of gear moving in the same area. This device is called R.S.T. Initial of "Radio Sol Train". The studies of implementation, and the first applications, are quickly realized at "Quatre Mares". To equip as quickly as possible all the series of machines, a program of modification is set up in 1989. During a few months, on the exit ways of the principal building of QM, the locomotives in revision and those "in chain" are mixed, causing a difficult management of the ways of the exit of the hall C.

Almost one month later, to Argenton on the Creuse, on August 31st, 1985, a derailment has for cause an overtaking of the speed authorized. This disaster was going to impose the necessity of thwarting any failures of the mechanic in the respect for the compulsory speed. Thus, it is decided to install on machines a system to continuously monitor the speed of the train (KVB). This system calculates by comparison between the introduced data, on the one hand by the mechanic (composition, length, type of the train) and the variables delivered by the internal equipment of the engine, in function inter alia speed, cabin in service etc. , and in addition by those transmitted of the way, recorded on fixed beacons, then transmitted by induction to the antenna placed under the locomotives, these beacons taking account of authorized speed, the stopping distance etc.

This comparison established a curve speed, and, in case of discrepancy with the actual speed of the train, triggers the emergency brake and cutting the traction. The prototypes of BB 67,400 and CC 72,000 are validated end of 1990 and that of A1AA1A 68,000 in early 1991 (the series will still not equipped thereafter). This year there, we see out of review and "specialty channels" the firsts gear equipped.

On August 6, 1988, in Gare de l'Est in Paris, a knocker is forced after the "no-cut" of the tensile force, at the braking of the train. Following what, he is set up on all the series, except the BB 63000, two particular devices, enslavement "Traction Braking" (ATF) and enslavement at the urgency (A.U).

The first, the ATF device is realised from the third quarter of 1988. Its actuation allows, during normal braking service and if the interruption of the tractive effort was not made, to automatically perform the same actions as the setting to 0 on the manipulator, that put idling the diesel engine and cutting the traction.

The AU is implemented since the beginning of 1991 on 72000 and on 67400 and 68000. This device has the effect of cutting the traction if the traction equipment are not returned to zero in the case of an emergency brake application by pressing a button in each cab called "Push Button Emergency. "The AU, like the ATF, does comprise any switch of insulation.

Thereafter, it was decided to equip the thermal machines circulating on single track with the DAAT (Automatic Stopping device of the Trains). This application that complements the other, will effectively cause the interruption of traction, and the emergency braking of the train, on the passage of a hook "signal off". The RST, KVB, ATF, AU, and DAAT are now applied on a large part of the park which QM is director.

The destruction of the AIA-AIA 62000 at the American design, and C 61000, and the increase in axle load wagons to maneuver in the triages, led the SNCF in 1990 at create two new series of BB 63000.

This will be the birth of BB 64700 and TBB 64800. The former are obtained following the transformation of BB 63500 at workshops of Nevers. The second at the radical transformation of BB 63000,at the workshops of Quatre Mares at first, and then in private industry.

The "Trucks", since that is how they are commonly called, are actually chassis of BB 63000 locomotives, where we have filed the cab and the motor diesel and shortened the chassis. Coupled with the BB 64700, which provided electricity, it contributes to the tensile stress, especially at start up of heavy trains.

In 1995 some BB 67000 are converted to BB 67200, they receive to QM a equipment enabling them to travel on TGV lines. Indeed, on these lines, the traditional signage is unsuitable for high speeds and has been replaced by a specific transmission. All signage is broadcast directly into the cabs by sensors placed under the locomotive. This device is called TVM (Transmission-ways-machines).

The evolution of maintenance cycles

Today, the documents have evolved. The agents are professionals.it is not need to be told which way you have to turn the screw to tighten. The quality of the documents that must precede the rigor of the repair techniques, these techniques are complicated by adapting to the actual degradation of the organs. On the other hand, the concepts of circulation safety, the potential of the organs are taken into account when drafting the documents.

The document has taken a legal value. It represent, before the law, the specifying of the work to be done (what we must do at minimum). In case of serious accident, a judge may use the document as a reference. It is therefore necessary to document the required quality.

The evolution of maintenance rules will be progressive and permanent. If initially the agents of the Study Group of QM are good technicians that did not care too much about costs, they quickly sought the optimum consistency of the work, for the sake of savings.

Today, they act as managers and do the best they can with the minimum of means. Adjust the maintenance, at the actual degradation is the main trend. This goal has become the challenge of today. Thus, since the start of the management of CC 72000 locomotives in the early 1970s, its maintenance cycle, ie the mileage between two RG has doubled. 800,000 km at the origin, he was taken stepwise at 1.6 million km (+ 0, + 15%).

DATES PERIODICITY

……………………………………………………………………………..

ORIGIN: RG 400 000 Km RL 400 000 Km RG

19-04-73 : RG 550 000 Km RL 550 000 Km RG

04-08-75 : RG 600 000 Km RL 600 000 Km RG

12-12-77 : RG 800 000 Km RL 800 000 Km RG

This is the result of a policy of investigations, who runs the locomotive maintenance, not toward systematic and important revisions , but toward the operations to one or more organs. The Investigations are studies on the search for reasonable limit, in matter of safety and reliability, for the maintenance of locomotives into service safely. They take account of progress related to technology and aim, over time, to increase the mileage of the machines. Today, while the locomotives have almost 30 years old, they are asked to do more mileage. Conversely a new series at the time should have been traverse 1,000,000 Km and the mileage should have fallen then. This policy choice was the same for all machines in the SNCF.

Recent studies conducted by the "Study Organisms" have helped to change the cycles of visits of locomotives (formerly managed calendar time) toward a program based on the itinerary realised. This works since January 1994. For a series like the BB 67400, the economy of maintenance cost induced MF is greater than 60 on the remaining life of the series to its theoretical amortization in 2005. With the same reasons of economy, the creation of an operation called "ATP" to replace the RL, will aim to reduce the revisions, to benefit from its maximum potential.

This change go bring workers of Q.M. to change their way of working. In RG and RL most of the work fell under the law of the systematic replacement. Thus, over the years the consistency of the RL had gradually confused with the RG dominated by systematic operations.

The ATP will be, for the chassis of the locomotives, a maintenance action to the criterion. It was thus necessary to be organized for apply a minimum of work in ATP.

In contrast, it became necessary to apply the maximum required in connection with the RG, to ensure cycle a trouble-free. The work of ATP, consists essentially to exchanges of the organs arrived at the end of their potential, it follows a saving in the cost of repair funds.

The maintenance at "criteria" requiring documents to date, the first work of the "Study Group" was to redesign, in priority, Inventory of work of Revision (ITR) and then perform Works Inventory of ATP to fully materialize the difference of consistency. Initially the study of the ATP had to be made in deposits. For reasons of workload, EIMM The QM has kept the implementation of these operations

Since 1992 is set up a new organization at QM under the name of SERM (Service of Etude of the Maintenance Rules). This service includes the "Organism" and the "Group" of Studies. Three reasons are the cause. The first is qualitative. When a study group had modified a rule of revision. And that monitoring and review should be completed by maintenance in deposits, it was necessary to ask the agency to amend the Inventory of Work of Visit and of the documents of visit under his charge.

These transactions resulted in many letters, of long lead times and sometimes of forgetful. The coherence of the rules of repair and of visit was be affected. The procedures were heavy for a rather poor result. The second reason was related to the rise in charge of the Atlantic and Northern TGV. By 1991, it was necessary to integrate in the existing organisms the rise to power of activity TGV. It was thus necessary to relieve them of certain loads. The third reason is organizational. The activity diesel is down, it was spread over three or four organism. Hence the idea for the activity diesel, consolidate agencies and study groups in the workshops thermal directors. A working group was charged to study the feasibility of the operation. QM assure the loads of organism of studies for series BB 67000 BB 67400, A1A A1A 68000/500 and the CC 72000.

The evolution of workshops and production facilities

The evolution of maintenance policy, and changes on the locomotives, will oblige the establishment to upgrade its production facilities.

the Years 1980 will bring the revival necessary. The multitude of industries in series to be realised on lathes, grinding machines, drill presses, has actually require, since the beginning of the Eighties, of important investments. Des tours programmables et des centres d’usinage, machines polyvalentes aux grandes possibilités de programmation, ont été installés continuant à donner à Q.M. la possibilité de rester un établissement de pointe dans le domaine de l’usinage.

The year 1985 will see the exchange of the overhead travelling cranes of 60 tons of the hall “C”, tired by nearly 70 years of service, and which by their outdatedness were presenting big problems of maintenance. The weight of the machines to raising, quite lower than that of the steam locomotives, and the taxes that such a power represents at the fiscal level will bring the revision downwards capacities of lifting of these bridges. Today, with 45 tonnes, the satisfaction of needs is assured. From that date several bridges of origin, all sides of the workshops, will be filed and exchanged.

The same year will begin construction of the painting booth, which in 1986 will give at QM the possibility of using modern processes in painting and complete, so, the quality of delivered to gear. This modern building was built in the Southern court of the establishment. It receives in its walls the machines per period from three to four days following a rigorous program based on its optimal use.

In 1988, and for to take into account the great movements of fight against pollutions, the establishment obtains a sewage treatment plant. The products of cleaning, oils and the hydrocarbons follow an obligatory forward progress bringing them towards settling basins then towards a particular device from where they emerge compacted and forwarded to authorized sites of reprocessing. Over the following years, various additions take place in order to increase and improve the volume and quality of the treatments imposed.

The year 1988 is also that of the arrival with Quatre-Mares of the computer tools to the service of the production. The use of this modern principle which is the use of the computing memory, often disparaged, will spread little by little. The problems posed initially by the recording and the information storage will quickly be controlled. The applications which will result from, will be useful to many places, of the offices to the workshops.

The problems posed by the storage of the parts in the various halls of QM, brings in 1989, to use the building remained vacant of the ex training college and to set up platforms of storage. These last take seats at places considered to be convenient according to loads to be supported. Thus, in the hall “A”, the structure to be set up was studied to receive the frames of bogies, another platform in the hall “B” supports the load of frames of engines etc. This implementation made it possible to reduce the obstruction of the halls considerably.

The interventions by machining on the frames of the diesel engines and the frames of the bogies require, of share their great dimensions, the work tables in proportion. These operations of high degrees of accuracy were carried out on machine tools “Cornacs” of an age advanced until 1993. the search for a modern machine answering the characteristics necessary leads this year to the purchase then the installation of a gantry milling machine “LINE” whose only four specimens exist in the world.

The gantry milling machine “Liné”

Although envisaged at the time of conversion to the diesel, it is in 1994 and to provide for the new needs due to the extension for the program of the revisions of the Pielstick engines, that a second stand of test-engine is construct.

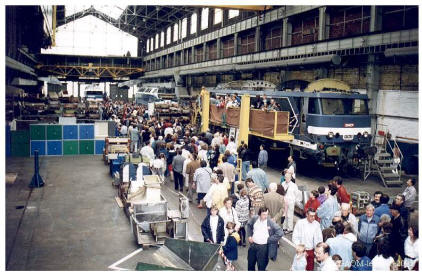

This year there, and for the first time, the Workshops of “Quatre-Mares” are open with the visitors. The agents of “QM”, proud of their technicality and their professionalism, will put all works, this day, for satisfy the few 8,000 people, who discover for the first time, the amplitude of the range covering the needs for the revisions of locomotives at the time of today.

A gold book, open for the circumstance, then makes it possible to the visitors to express their astonishment. A good amount of between them, which frequently skirted the workshops, by the street of Paris, did not imagined the size of the various buildings. Others are surprised when the overhead travelling cranes bring from one end to another of the hall “C”, a locomotive DC 72000 whose weight represents that of approximately a hundred cars.

This day is also the opportunity to present, before being returned to the museum in Mulhouse, the CC 65001 whose restoration was done by some voluntary agents QM.

© GAQM2016 joel.lemaure@outlook.fr