![]()

THEME VI

THE RECONSTRUCTION

(from 1944 to 1947)

1st period: from April 19th to June 30th 1944.

After clearing the rubble, as it was impossible to envisage the immediate

reconstruction of the destroyed or damaged buildings, it was decided to start

right away with the construction of individual shelters for the machine tools

and certain metal workers’ benches in order to protect them from the weather. It

is also decided to make every effort to have ready for when the appropriate time

came, everything necessary for the reconstruction to proceed, that is to say

compressed air, electricity, water, and tools. This stage was completed in 1944.

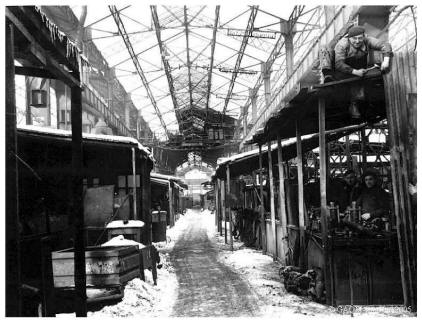

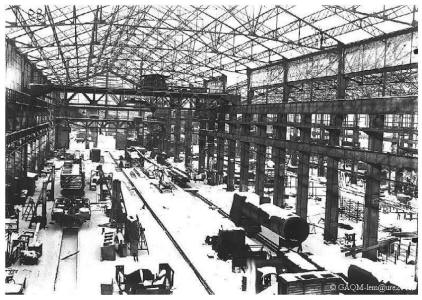

Makeshift shelters in the hall "D"

It was made easier by the fact that the electricity sub-station had suffered little: the transformers, compressors, and the oxygen and acetylene plants were practically intact.

The Paris side of building F and the brake workshop, having suffered the least from the April 19th bombing, were back in action on May 24th 1944, at least for hand-made items.

The auxiliary pumping station next to the building housing the “trommels” used for cleaning and de-scaling boiler tubes, which was designed in 1939 to stand up to anything, was also re-commissioned on May 24th.

This made it possible to supply water to the Niclausse boiler in the fitting shop which was used for testing pumps and compressors, and then later, for cooling the shop’s air compressors.

The electricity substation in the "Paris end" works yard had not been hit either so the machine tools in the brake shop were back in service at the beginning of June.

The compressors were back in service on June 28th and after a month spent clearing rubble, work resumed in the central machine shop. From June 1944, the elements indispensable for the reconstruction already existed.

2nd period: from July 1st to the Liberation.

From the beginning of July until the Liberation on August 30th, in view of the frequency of air raid warnings, practically no work was done. In fact there was a total shutdown from August 24th until September 4th 1944.

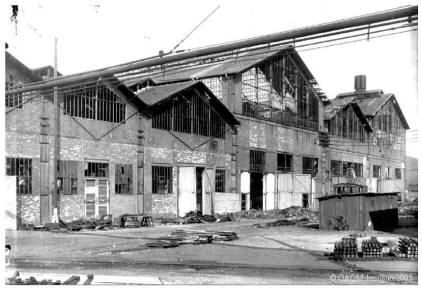

The "Paris" end of the main buildings

3rd period: from the Liberation to spring 1945.

From September 4th, the 691 employees who had stayed in the Rouen region returned to work with a will and the regional department "Matériel et Traction Ouest" made the reconstruction of QM a top priority, at the same level of importance as the MPDs. The electricity supply was restored on September 13th but only up to a total capacity of 500 kWh a day, which corresponded to approximately 1/40th of the normal requirements.Until October, it was just a question of backfilling bomb craters, clearing rubble, demolishing damaged roof sections, repairing the various ducts and pipe runs, and getting the overhead travelling cranes back into service.

The 3.5 tonne crane in Building F was restored to service on September 14th followed by the 60 tonne erecting shop crane just one week later. With the completion of this work, all was more or less ready for a resumption of activities.

The "Rouen" end of Building "A"

The forge shop was at work five days later, and the steel boiler shop on the Paris side was soon back in action under almost normal conditions, housing part of the staff of the erecting shop who were engaged on accident repairs.

But from a railway point of view, Sotteville was completely isolated and there could be no question of taking on work which required large volumes of materials. It was necessary to wait for the restoration of the Longs-Vallons viaduct on the Rouen – Serquigny line and of the Melville connection by the Canadians so that the first wagons could reach QM in December 1944.

The first train from Rouen to Saint-Pierre-du-Vauvray via Louviers did not run until November 28th. Before then, all supplies depended on road transport.

In other words, the winter of 1944-45 saw only a partial reconstruction of QM. Only one building had been made weatherproof and so with the snow, working conditions were very difficult.

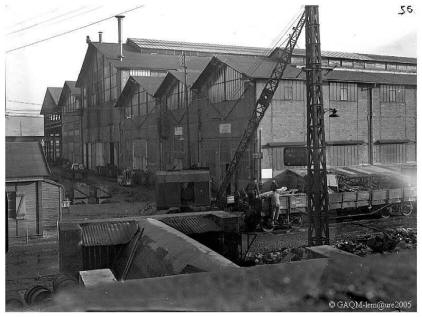

Building "C" under the snow

On May 31st 1945, to celebrate the railway employees’ National Day, QM was honoured with a visit by a hundred-strong delegation from Alsace and Lorraine accompanied by the Strasbourg railway band. This organisation, noted for its resistance to the Germans, had been relentlessly pursued and harried by the occupying forces in an attempt to break it. Along the route of the procession organized for the occasion and consisting of the band preceded by Alsatian women in traditional costume, amongst the serried ranks of the workers in their overalls, there was more than one who was moved to tears at the sight of their large silk headdresses symbolising the victory.

4th period: from the spring to autumn 1945.

In the spring of 1945, the shortage of materials was less acute and the end of hostilities in Europe allowed the return to commercial use of lots of trucks and wagons. Because of the scale of the destruction, the needs were enormous. 1500 tons of bricks, 750 tons of cement, 130 tons of steel frames, 1,600 cubic metres of wood and 35 tons of mastic would be used in the reconstruction of QM.

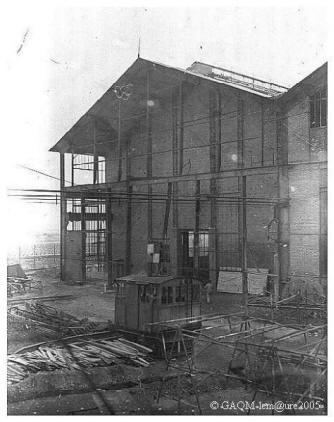

The "Rouen" end of the main buildings

In spite of the extent of the work required, confident that everyone would make an effort and considering that by the start of winter 1945-1946, the repairs would be well enough advanced to permit work in acceptable conditions, the workshop management took the decision to bring back the evacuated staff: so the spring and summer of 1945 saw a rapid increase in the number of personnel.

5th period: 1946-1947. The resumption of activities at Quatre-Mares.

On January 1st 1946, the walls and roofs, as expected, were finished. This success required 60,000 working days. German POWs made their contribution to the resumption of activities in the workshops until 1948. But the fitters shop had only half of its pre-war facilities: it appeared to be empty of machine tools. In fact most were still in individual shelters. They were old, worn out prematurely by intensive use and exposure to the weather. Only the presence of new shapers and drilling machines indicated that the re-equipment of QM was in progress.

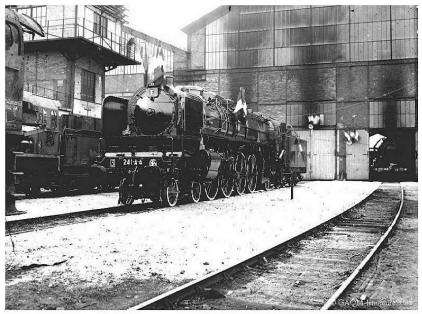

241-A4 repaired and ready to re-enter service

May 1st 1946 was the opportunity to celebrate the out-shopping of the 100th locomotive to be repaired after the Liberation. “Mountain” 241-A4, fresh from the paint shop and decorated for the occasion was the star of the show. The event marked the end of the pioneering days of repairs depending on sheer willpower and ushered in a regime of high productivity. In December of the same year, the scene was very different. 150 modern machine tools, for the most part of British or American origin, put QM among the best equipped workshops with a production capacity well surpassing that of 1938.

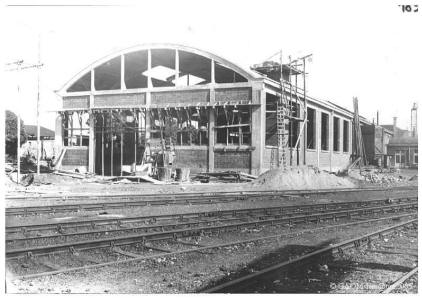

The rebuilding of the main offices

Construction of a large building for the new administrative offices and methods engineering office, as well as the doctor's surgery, began in February 1946 and was completed in July 1947. Following the destruction of the original building, they had been housed in wooden huts in the Rouen end yard. During this same period, the training school was rebuilt, along with new accommodation for the boarders.

The rebuilding of the training school

The years 1946 and 1947 also saw the removal of over 11,000 tons of rubble and 8,000 tons of scrap metal from the workshop site.

1947 would be a year of continued re-equipment and the rational use of the means of production.

Since the autumn of 1944, the state of the steam locomotive fleet had become catastrophic. Out of 17,259 machines on the stock list of the newly created SNCF in 1938, two thirds had been destroyed or put out of action by air attack, sabotage, wear and tear in the service of the occupying forces, or else deliberately put out of action by railway workers in order to hinder the retreat of the enemy. For want of the necessary materials and manpower, others were immobilized awaiting repair. French industry had been forced to work for the German war effort and had hardly made any contribution to the modernisation of the traction department’s fleet. The result was that many locomotives due for the scrap yard had had to be maintained in service.

The resumption of the activities at QM was thus marked, after the war, by an influx of locomotives in a very bad state of repair from all over network.

An example of this was the "Pacific" from Mantes which was pierced with 365 holes, one for every day of the year.

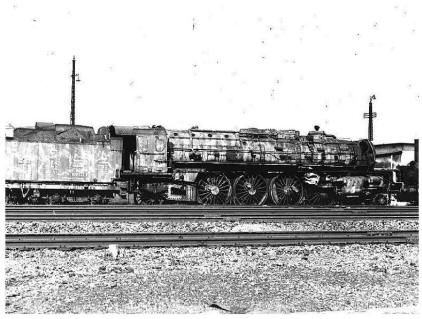

Some "Mountains" used by the German railways as mobile steam plants in Berlin returned to QM in 1945 and 1946 in a seriously damaged condition and still in their German camouflage livery.Faced with the impossibility of rapidly repairing the enormous quantity of damaged material, and with a grievously weakened French industry unable satisfy the urgent demand for a thousand machines, the government turned to the United States whose industrial base was well tuned to meet the enormous needs of the war machine. Contacts had been made in 1944 which enabled the setting-up of a mission to study the needs of a post-Liberation France. A vast manufacturing programme was born of the many negotiations that had resulted from it.

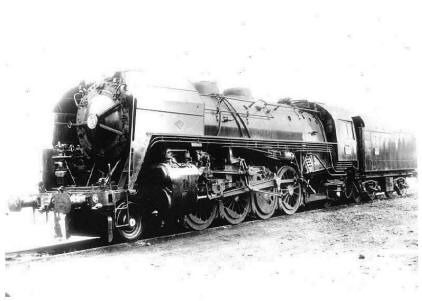

The choice fell on "Mikado" type machines and France would order 1340, all carrying the class number "141 R". These locomotives, built in the United States and Canada and known as "Americaines", were delivered between 1945 and 1947. Together with the repair of the existing material, they considerably aided the resumption of railway activity.

The transport by sea of these machines from the American continent to France was a success. 1340 locomotives and their tenders as well as a stock of spare parts were loaded for the 6000 kilometre trip. However, not all the machines made it. On April 13th 1947, Norwegian heavy-lift ship M/S Belpamela foundered off Newfoundland with its cargo of 16 141-Rs, numbered 1220 to 1235.

Among the machines originally equipped for coal burning, several were subsequently fitted to burn oil fuel.

Coal fired 141-R Oil fired 141-R

141 R 1 à 700 141 R 821 à 860

701 à 820 961 à 1020

861 à 960 1121 à 1200

1021 à 1120 1221 à 1340

1201 à 1219

With Western Europe in the grip of a coal crisis, French collieries were obliged to give priority to supplies to the iron and steel industry, essential for the nation’s reconstruction. So in 1947, except for 141-R 1 to 700 and 1201 to 1219, the coal burning locomotives were converted to oil. The work was carried out at the Nevers workshops and at the "Ouest" running shed in Niort.

translation by John Salter

© GAQM2016 joel.lemaure@outlook.fr