![]()

THEME VIII

THE SWITCH TO DIESEL

(from 1964 to 1972)

The Diesel conversion

In 1963 is set up to QM the " Service Diesel Conversion " to allow the transition of the activity "Vapor" at the activity "Diesel" .

To undertake the revisions and the accidental repairs of the diesel locomotives of power superior to 1500 kilowatts ( 2000 horses), a project of conversion of workshops is presented to the Ministry of Transport and accepted on March 2nd, 1965.

For the workshops of Quatre-Mares, the conversion from steam to diesel means a complete change in its activities and organization, in terms of material and labor. However, these changes correspond to the four principles set by the Department of economics, organization of workstations, application of techniques specific to diesel, and finally implementation of new guidelines.

From the financial point of view, the conversion of the workshops must be made with the least possible expense. This means there is no question of expansion. The only permitted investments relate machine tools specific to the activity diesel.

The constraint imposed by the conservation of buildings requires to reorganize their interior spaces. A new organisation of the operations is defined. The handling and the storage of parts are rationalized according to the new operations. The whole is made possible by the realization of long runways serving every workshop. The meaning of input and output of locomotives is reversed to facilitate the construction, low cost, facilities such as test rigs, equipment calibration, and storage for fuel, at the side "south". In all the workshops, the technique of the diesel involves a perfect cleanliness of places, a separation of places and construction sites, of cleaning, of dismantling, of wash, repair, and their regular cleaning.

The repair of the diesel engines involves, in addition, the control and the try of parts at every stage of the maintenance, what requires the installation of bench-tests. (Example of pumps with injection). At the level of the work particularly, the conversion entails new objectives. It is the reduction of the durations of fixed asset of locomotives, the application of the new methods of maintenance of machines, the quality of the work, and finally a bigger follow-up of cost prices by the definition of the costs of repair minimal.

These guidelines are implemented in stages with success, since the plan originally intended is observed, demonstrating the adaptability of QM.

The three stages of its realisation

This conversion, taking into account the disappearance of activities related to the steam, took place in three stages.

It was during the year 1965 begins the first. Its purpose is to allow the transactions of limited revision of the diesel-electric locomotives. The first diesel engine, in this case the A1A-A1A 68001, enter into limited revision in October 1965 and resumes service in mid-November.

This stage is characterized mainly by the commissioning in late 1966, a position-calibration used to electrically simulate the pull of a train, and thus validate the overall operations of revisions made. It is also the realization of the first posts for the limited review of diesel engines (MLR) in the northern part of the assembly hall. The side south, meanwhile, continues the repair of steam locomotives. The workshops continue the repaire of certain organs of steam locomotives, called "stock parts" for deposits until 1970.

It is between 1966 and 1970, and to end a mission dedicated in the service of the "Vapor", that the workshops of Q.M, have reconditioned, for the Museum of the Railroads of Mulhouse, four steam locomotives.

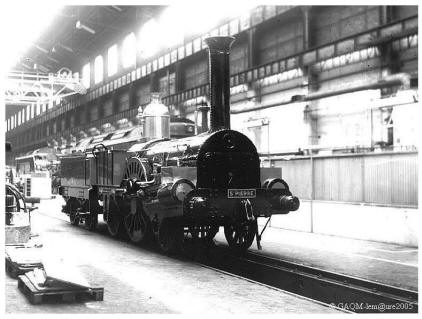

The St PIERRE

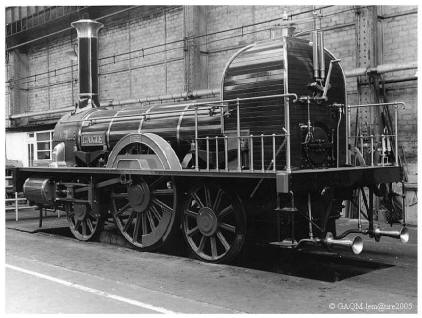

The Eagle

The St Pierre ‑ builder "Allcard Buddicom Chartreux" in 1844

The eagle AM6 ‑ builder "Stephenson and C°" in 1846

The 030 TA 628 ‑ builder "Compagnie de Fives Lille" in 1873

The 241 A1 ‑ builder "Chemins de Fer de l'Est ateliers d'Epernay" in 1929

Some volunteer organisations maintain a few survivors of that great epoch. This is the case of the "Pacific Steam Club" Sotteville-lès-Rouen with the "231 G 558", property of the Association of Heads of Traction - Network Atlantic and included in the inventory of historical monuments.

Among machines, at present protected by the other associations, some, by which the numbers follow, are passed by QM

141 TB 424 (de l’Est) (6/58),241 P 36 (12/60) (4/62),141 R 1332 (12/61) (11/67),

241 P 16 (1/61) (5/62) (5/67),141 R 1108 (4/67),141 TD 740 (9/59) (4/66),

241 P 17 (5/61) (7/62) (9/66),141 R 840 (6/67),241 P 9 (6/61) (4/63) (1066),

141 R 1187 (10/56) (1/68),

The second stage, which begins at the beginning of year 1967, has for objective the realization of jobs necessary for the general revisions of the electric diesel locomotives. She is characterized by the starting, at the end of 1969, of the first test bench of heat engines and first posts for the general revision of engines ( R.G.M).

The third phase in 1972 saw the completion of the conversion of buildings to diesel, and the end of steam activities.

The training of the staff

The conversion of the workshops of QM is going to be accompanied with a tremendous effort of training. The technique of the electric diesel is completely new and unknown of the agents in position. From 1965 the "Conversion service" insures the training of the agents at the new notions of the diesel-electric drive as well as in the new methods of work which it entails.

The gradual transition from steam to diesel will help to train staff without causing a shutdown of the workshops. However, it is not possible to directly form the set of agents. An investigation is conducted within the company for identify the agents most likely to take training in diesel-electric traction. Based on the volunteerism, the training is seen by some as a means of internal promotion. Young workers, recruited from among the companions, volunteered for this training which requires still some personal sacrifice. They will be responsible for disseminating the knowledge in the workshops.

teaching begins with an pre-training course, taught by agents of the network, on the general principles of operation of the diesel-electric locomotive. These bases acquired, the graders continues their education in schools SNCF of Nantes and Nevers. Agents are sent to training in engine manufacturers, the SACM to Mulhouse or the S.E.M.T. Pielstick to Montoir.They return to QM with the plans and methods of repair of engines that are the complement of the education provided by the trainers of the SNCF. Others are also sent to the CAFL, Ferroniere factory in St Chamond, for the part bodywork and bogies. The purpose of these courses and these training is to teach officers the principles of operation of machinery but also the repair methods. It must indeed set the working time for different operations and the organisation of work itself in the workshops. It is thanks to the staff so trained , and through the broadcasting of working index cards, that the conversion of the workshops of QM is a success. However this conversion is finished only in 1974.

The transition period

For two and a half years, we see in the assembly hall to meet, steam engines and diesel engines. In 1967, the vapor activity represents 65% of the total activity of the establishment.

The interventions concern, thus, about fifty 141 R, and six 241 p. The part " Steam locomotives " is folded up in the side "Paris" of the workshop " assembly", called henceforth " hall C ". All activities "boilermaking" are concentrated in the half of halls B and C, regarding the work on the boilers. The activity of the workshop of the "forges" sees its repair activity of "tubes at smoke" greatly reduced . Two "power hammers" stays temporarily in service. The general mechanics of halls D and E, further to the decline of the preparations and further to the decrease of the stocks of spare parts for the vapor, withdraws and himself gathers together gradually into the two half-halls D and E which are him reserved. The workshop of the wheels, in mixed activity, is rearranged because of the transfer of the bogies of the Autorails whose the repair of which is added to that of the diesel axles and vapor.

The revisions of the electric diesel machines represent, as for them, 35 % of the activity of QM, with a monthly average of 2 RL and 3 RA. The interventions carry, on the series, A1A-A1A 68000 and 68500, BB 69000 ( 2 prototypes), CC 70000 ( 2 prototypes).

Their natures are:

- RL: Limited revision (4 600 hours for one 68000),

- RG: general Revision (4 900 hours for one 68000),

- RA: accidental Repair.

In this year of 1967, the on-surface division of workshops is 55 % for the activities vapor and dependente, 28 % for those bound to the diesel and 17 % in the course of arrangement.

The most significant projects completed include:

- In Hall C, the post-job of degassing(emptying water, oil and gasoil) and cleaning, the four positions "Révision Limitée Caisse" each of which is adjacent to a position of "Révision Limitée Moteur".

- In Hall B, the post-job of specialized sites "Injection", "cylinder head" etc. .. for the revision of diesel engines.

- In Hall A, the post-job of"Radiators", the cleaning area consisting of several specialized bathroom, tunnel cleaning with rinsing ramp built, a post "Bogie" used temporarily for the disassembly and reassembly.

- Finally, Halls D and E respectively have the embryos of review sites of electric motors and various electrical equipment.

Outside, the post of calibration with "remote control" of the locomotive is in service.

The reorganisation of services

The evolution of the number of staff and of activities, realization of the plan of conversion of workshops, and the progressive application of the new directives relative to the organization of the maintenance of the modern equipment, are driving to improve and to adapt the means of management and information to assure a wide training program of the staff and to produce as one goes along the new documents and the new rules of maintenance and to assure their broadcasting.

Taking into account the new guidelines, as well as conversion to the workshops, the functional organization of workshops in conjunction with the conversion, undergoes some changes. The organisational of the workshops are readapted for provide for new connections needed between the different services where are located stations or groups responsible, responsible for launching documents, instructions and application. These new positions have their counterparts at regional and national level, the first called "Regional Services" and the second "Organism". This is in the connection with the "Service Methods" (TM), of the creation of a "Groupe d'etude" and from the "Poste-organisation",in charge of the implementation and of the preservation of the organization of the establishment, of the distribution and of the name specific distribution of documents.

The service "Methods" prepares the work, studying the methods of manufacture and repair. It develops projects for installation of functional sites, using rational handling equipment available, and applying the basic principles of ergonomics and design correction. He supplies in the service of the distribution ( TR) the index cards of manufacturing and repair, the tables and the documents of expertise allowing the pricing for the works. He insures the relations between QM and the divisions of studies.

The Group of study is loaded with of élaboration of the booklets of revision, which record all the works to be made on machines to be handled, as well as index cards of repair which specify modus operandi by underlining the difficulties.

The agents of the service "Technique-method" in "Section", who depend on the "Post-Organisation", assure the connection between the Heads of Sections and the TM office. They solve the problems which can be handled on the spot and are keeping a file of intervention. Their role of connection and adviser is important.

The Sections, which are quickly nammed"Divisional Workshop," with better geographical grouping, are now considered as much of establishment with the greatest possible independence for the management and the application of instructions. It is thus that each "Section Chief" has the powers of Head of School and the corresponding responsibility. In particular, it follows, under its authority, programs, deadlines, cost, charges the groups-section, distribution of documents, the holding of "log-books", and of documents of corresponding interventions.

A service " Technical Management ", placed under the direct authority of the Head of District, is created and makes sure of the correct application of the projected plan of accounting and presents the results of management. He interprets the statistical and countable results.

A service " Technico-Social " loaded of the studies of posts, of examinations of behavior, of the social inquiries and of the material organization of the training, considering needs expressed by the services is also created. He has for it of correspondents in the big sections, called a foreman of vocational guidance.

Buddicom appendix of Quatre-Mares

It is the January 1st, 1970 that the Workshops of "Buddicom" are connected with the workshops of "Quatre-Mares". In its enclosure are installed 3 workshops.

The first, named "workshop of springs", factory and repairs, since December, 1968 the totality of the leaf springs of the S.N.C.F.. This workshop executes in chain, the manufacturing of blades and the repair of springs. The Machines of benders and at "soak" very precise allow perfectly regular heat treatments and allowed to eliminate any manual fitting of blades. The ovens work at the town gas or in the heating gasoil, and the enfournement of blades, is automatic. The regulation and the control of the completely automatic temperatures is obtained by electronic devices enslaved in thermoelectric couples. Specialised hydraulic presses allow the hot or cold bridage.

The second workshop is equipped with the equipment necessary for the repair of axles (we hear by axles: the axis, the wheels and the boxes of axles) of all the towed material, including those of the trailers of railcars. The production averages of 450 axles gone up a month among which 160 approximately with replacement of wheels bandagées by wheels monoblocks.

The third, workshop of plastics, manufactures a wide variety of components or parts of locomotives and carriages and wagons in stratified polyester. All plastics are made from glass fabrics and synthetic resin (styrene) that are applied on the molds in layers successive or by a special gun that diffuse simultaneously fiberglass and the resin on an appropriate form.

To give an idea of the hardness of these plastics, they cannot be worked, if necessary , that by tools in carbide of tungsten or with at the tip of diamond. The work consists moreover only in a possible deburring, obtained parts being always with the dimensions of finish and with a beautiful aspect. His activity began in February, 1957 and its first realizations have consisted at the frame of bays and mouldings of cars.

In 1972 this workshop makes among others, basins, floors and doors of Toilets, doors of access of cars, ventilators of roofs, tanks 400 liter drinking water , and doors of visits of diesel engines. The most important parts are represented by the driver's cabs of locomotives BB 67000, AIA AIA 68000, CC 72000, these last ones who can adapt itself to the CC 6500. This workshop also made the profiled extremities of the experimental turbotrain ( T.G.S) of the turbotrain E.T.G. and certain number of those intended for the R.T.G..

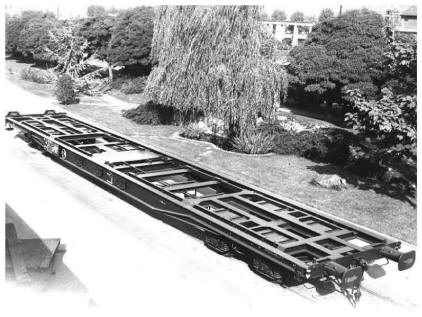

The Wagons "carrier of transconteneurs"

It is with the exit of a prototype, 09-09-1968, that begins to QM the construction of a series of cars intended to circulate in "trains blocks". These cars have dimensions conceived to allow a load of transconteneurs of 10, 20, 30 and 40 feet in some combinations as well as containers multiple base of 5 feet. These wagons are built in chain with an exit of a wagon a day. It is about a work of prefabrication very pushed by three main parts of the frame who understand central girders and both extremities. The assembly of these three parts is made on mannequin and the soldering on vireur. April 4th, 1969 takes out of QM the 100th wagon. Among the peculiarities of these cars we can quote the organs of brake with compressed air the power of which is studied to vary automatically according to the load. Approximately 400 hours are necessary for their construction, of the preparation of elements at the delivery of wagons. Equipped by 2 bogies Y25D their length is 19m, 720 and their vacuous total weight is 19t, 500.

© GAQM2016 joel.lemaure@outlook.fr